Innovative Technology Reduces Mercury Emissions to Keep Ohio’s Sewage Sludge Incinerators Hot and Costs Cool

![]() At the 2017 WEF Residuals and Biosolids Conference, Black and Veatch presented the success story of the NEORSD (Cleveland, OH) and MSD of Greater Cincinnati’s waste water treatment plants evaluation and selection of the EnviroCare MercuryPak scrubber. The equipment was selected to meet sewage sludge incineration (SSI) mercury compliance for both major municipalities. The EnviroCare MercuryPak scrubber utilizes Sorbent Polymer Composite (SPC) materials invented and developed by W.L. Gore. EnviroCare adapted the technology for specific use in SSI in response to new US EPA emission regulations. Through market specific testing, continuous product development, and implementation at some of the largest waste water treatment plants in the United States, the MercuryPak scrubber has become a proven cost effective solution for the worlds most stringent SSI mercury emission regulations.

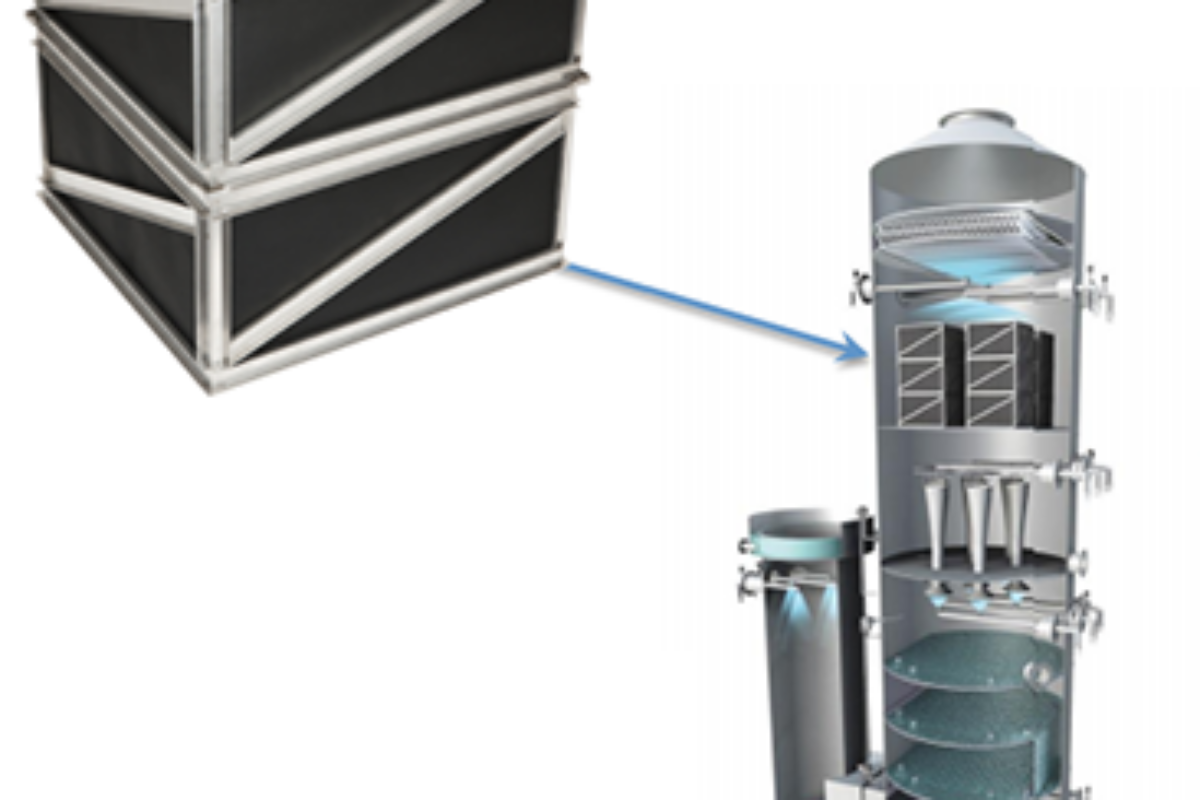

At the 2017 WEF Residuals and Biosolids Conference, Black and Veatch presented the success story of the NEORSD (Cleveland, OH) and MSD of Greater Cincinnati’s waste water treatment plants evaluation and selection of the EnviroCare MercuryPak scrubber. The equipment was selected to meet sewage sludge incineration (SSI) mercury compliance for both major municipalities. The EnviroCare MercuryPak scrubber utilizes Sorbent Polymer Composite (SPC) materials invented and developed by W.L. Gore. EnviroCare adapted the technology for specific use in SSI in response to new US EPA emission regulations. Through market specific testing, continuous product development, and implementation at some of the largest waste water treatment plants in the United States, the MercuryPak scrubber has become a proven cost effective solution for the worlds most stringent SSI mercury emission regulations.

The use of the EnviroCare MercuryPak scrubber eliminates the contamination and disposal issues of dry ash associated with mercury reduction using activated carbon injection in a baghouse. Elimination of mercury adsorption in the baghouse may provide options for beneficial use of the dry ash in some facilities. The MercuryPak technology is perfectly suited for the saturated environments created with acid gas absorption in wet scrubbers and is not susceptible to common problems associated with wet environments in activated carbon beds. It also eliminates the need for large gas conditioning systems and additional mist eliminators simplifying the installation and reducing the installed footprint.

Contact EnviroCare to find out more about this advanced innovative technology.

The technical paper presented by Black & Veatch can be downloaded by clicking on it below.